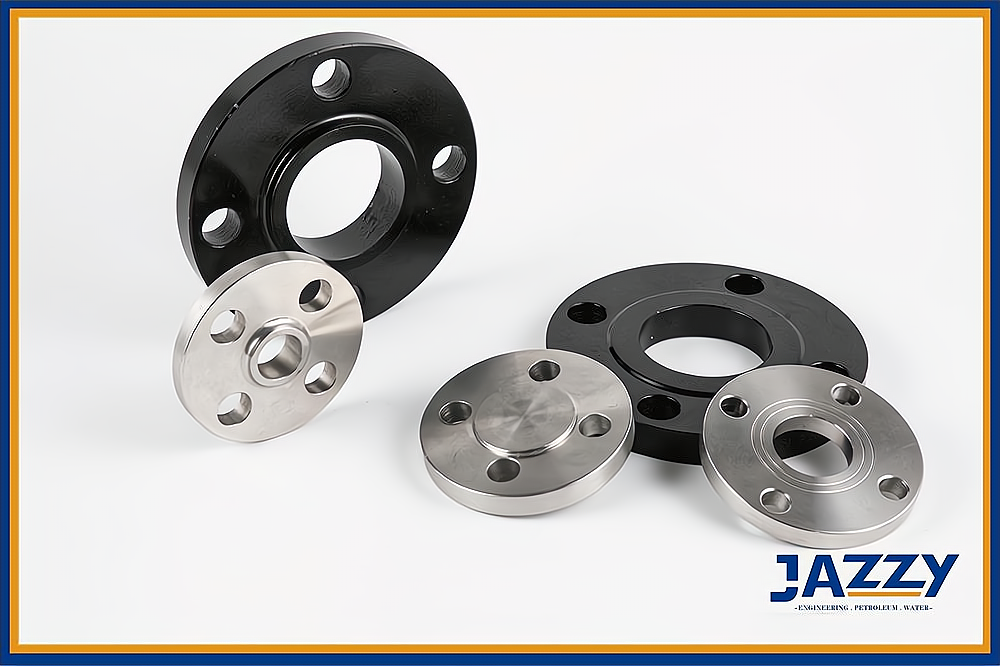

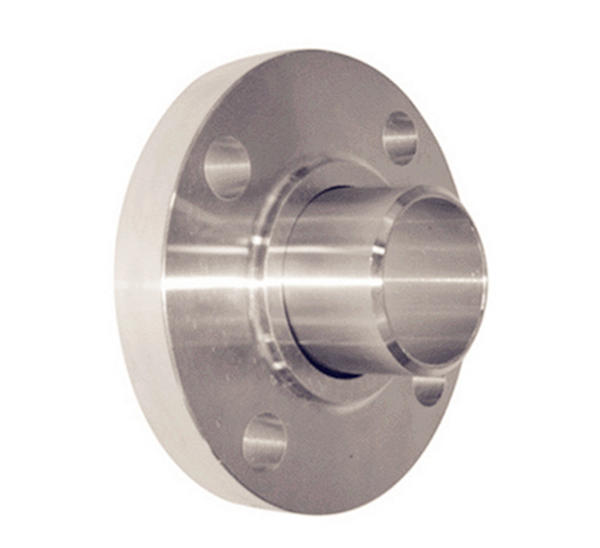

Forged steel flange has higher precision and performances than the cast flange and widely used in different industries for connecting equipment or pipelines, especially for high temperature and high pressure environments.

Forged flange is a plate-type device, usually in circular appearance which could be attached the ends of pipes, fittings, valves or other objects to facilitate assembly and dis-assembly of the piping system. It offers impressive mechanical performance as a connecting parts.

Connection Types

Raw Material for Forged Flange

Forged steel flange raw material generally is pipe billet, after cutting the billet then continuously hammered it, in this way to eliminate the defects such as segregation and looseness in the ingot.

Material Standard

Forged steel flange material normally are carbon steel, alloy steel and stainless steel.

Stainless Steel Forged Steel Flange: ASTM A182 F304, F316

Alloy Steel Forged Flange: ASTM A182 F5, F9, F11, F12, F21, F22

Carbon Steel Forged Flange: ASTM A105, ASTM A694 F42, F46,F52,F60, F65 and F70, ASTM A350 LF2

ASTM A182/ A182M

This specification covers forged low alloy and stainless steel piping components for use in pressure system. It includes flanges, fittings, valves, and similar parts to specified dimensions or to dimensional standard.

ASTM A105

For forged carbon steel pipe components, namely flanges, fittings, valves and similar components, for pressure systems at ambient and high temperature conditions.

ASTM A350/ A350M

Standard Specification for Carbon and Low Alloy Steel Forgings,

The specification includes several grades of carbon and low alloy steel forged or ring rolled flanges, forged fittings and valves, primarily for low temperature service and required notch toughness testing for piping components

ASTM A694/ A694M

This specification covers carbon and alloy steel forgings for pipe flanges, fittings, valves, and parts for high-pressure transmission service.

Forged Flange Pressure Ratings

Class 150 lb

Class 300 lb

Class 600 lb

Class 900 lb

Class 1500 lb

Class 2500 lb

Forged Steel Flange Advantages

Manufacturing Processes

The forging process generally consists of the following steps:

Selecting high-quality billet blanking

Heating

Forming

Forging

Cooling

Manufacturing Standards Referred

ASME B16.5: Dimension standard for steel pipe flanges and flanged fittings

ASME B16.47: Large diameter steel flanges NPS 26 to NPS 60

MSS-SP44: For steel pipeline flanges

API 605: For large diameter carbon steel flanges

Technology and Method of Forging Steel Flange

Its technology and method includes free forging, die forging and fetal membrane forging. According to the quality of the forgings and number of production batches, different forging methods are selected.

Free Forging

The free forging productivity is low, the machining allowance is large, but the tool is simple and the versatility is large, so it is widely used for forging a single piece and a small batch of forgings with a simple shape.

Die Forging

The die forging is collectively referred to as model forging, in which the heated blank is placed in the forging die fixed on the die forging equipment.

Differences between forged steel flange and cast iron flange

There are mainly two methods to manufacture the flanges: Forging and Casting.

Cast Iron Flange

Cast flange is a lower cost flange and suitable for medium or low pressure pipelines. It has below features:

High production efficiency and low production cost.

Could made to a more complicated shape and with lower a cost.

The blank shape and size of cast steel flange is accurate, the processing quantity is small.

Have casting defects, such as porosity, crack, inclusion.

The internal flow of the casting is slow.

If it is a cutting part, the streamline type is worse.

Forged Steel Flange

Forged flange generally have lower carbon content than cast iron flange, so they are not easy to rust.

It has good streamline shape and compact structure, so their mechanical properties are better than cast flange.

If the forging process is improper, the grain will be large or uneven, and the hardening crack will occur. The cost of forged steel flange is higher than that of the casting flange.

Forgings is compatible with higher shear and tensile forces than castings.

The internal structure of the forging is uniform, and there are no harmful defects such as pores and inclusions in the casting.