The 10 commandments of sanitary design principles were created when the North American Meat Institute (INAM) identified research related to the elimination of Listeria as one of its top priorities in 2001 for developing sanitary fittings design principles for equipment that meet the expectations of the meat and poultry industries.

Establishing industry-wide specifications benefits the entire industry by promoting a standard that will help reduce contamination and associated recalls. These principles are appropriate for equipment in all food uses, including the production of pet food and pet products.

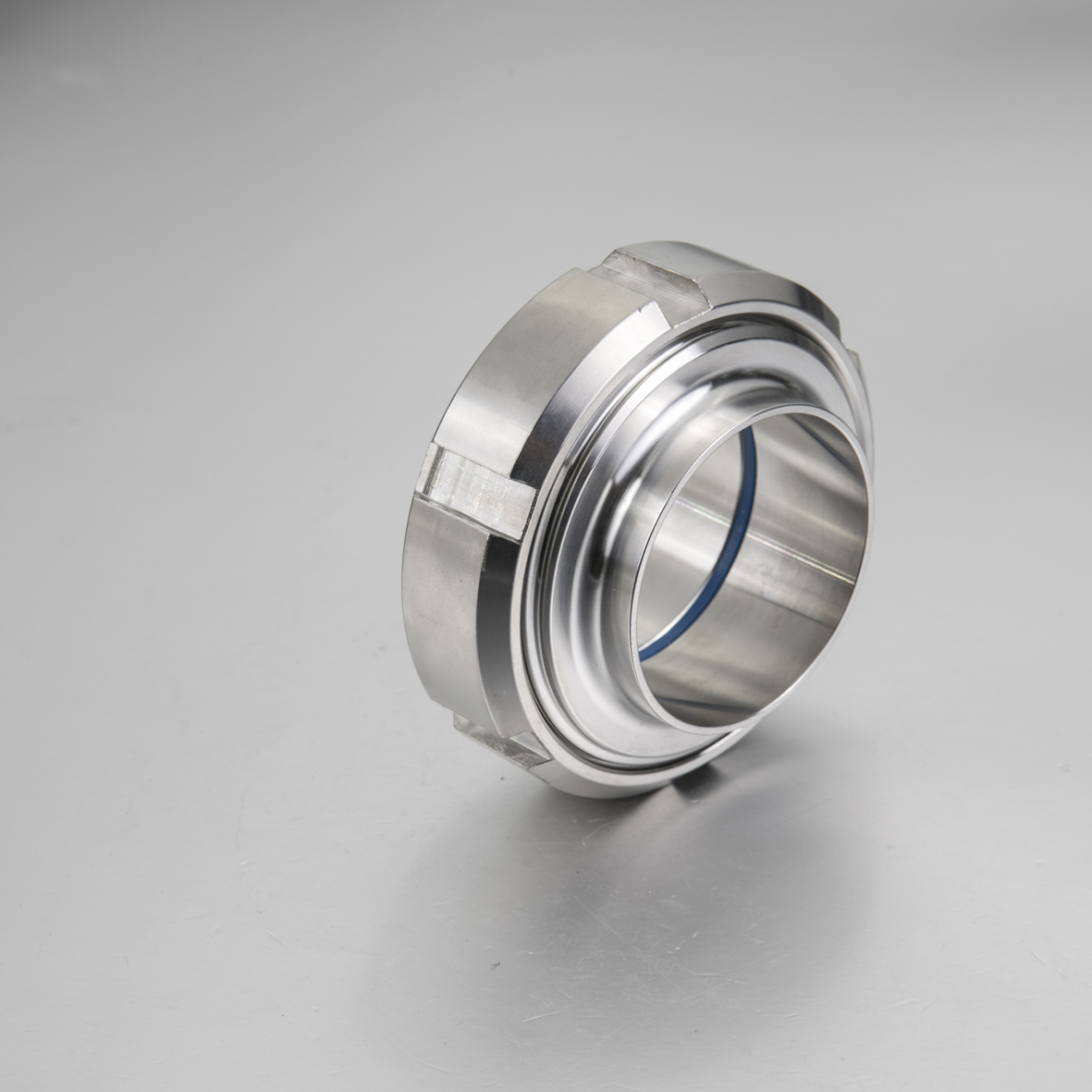

To reduce the risk of microbiological contamination outbreaks, all product inspection equipment should be designed with due consideration to the application, operating environment, and cleaning regimes likely to be encountered, and should adhere to the following 10 principles of sanitary fitting design.

1. Microbiologically cleanable to prevent bacterial growth on equipment contact surfaces, whether produced or not.

2. Made of materials compatible with the product, environment, and cleaning and sanitation methods.

3. Accessible for inspection, maintenance, cleaning, and hygiene without the use of tools.

4. No product or liquid collection. The equipment should be self-draining.

5. The hollow areas must be tightly closed. Bolts, mounting plates, brackets, and other such items must be continuously welded to the unattached surface by drilled and tapped holes.

6. No niche. Equipment must be free of niches.

7. Health operational performance. The equipment must operate in such a way that it does not contribute to unsanitary conditions.

8. Hygienic design of the maintenance enclosures to ensure that the food product, water, or product liquid does not enter or accumulate in and on the enclosure or interface.

9. Hygienic compatibility with other plant systems such as electricity, hydraulics, steam, air, and water.

10. Validated cleaning and disinfection protocols must be clearly written, designed, and proven effective and efficient.