- Application

- Products

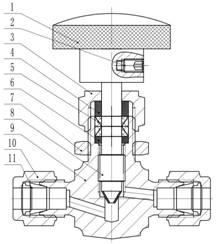

- Stainless Steel Valve

- Stainless Steel Pipe Fitting

- Stainless Steel 90 Degree Elbow FXF

- Stainless Steel 90 Degree Elbow MXF

- Stainless Steel 45 Degree Elbow FxF

- Stainless Steel Equal Tee FXFXF Fitting

- Stainless Steel Hexagon Nipple MXM Fitting

- Stainless Steel Reducing Hexagon Nipple MXM Fitting

- Stainless Steel Union MXF

- Stainless Steel Cross FXFXFXF

- Stainless Steel Hexagon Bushing MXF Fitting

- Stainless Steel Hose Nipple FXH Fitting

- Stainless Steel Barrel Nipple MXM

- Stainless Steel Hexagon Cap Fitting

- Stainless Steel Hexagon Plug Fitting

- Stainless Steel Reducing Socket Banded Fitting

- Sanitary Fitting

- Instrument Fitting

- Instrument Hexagon Nipple Fitting

- Instrument Long Hexagon Nipple Fitting

- Instrument 90 Degree Elbow FXF Fitting

- Instrument 90 Degree Elbow MXM Fitting

- Instrument Union Elbow Fitting

- Instrument Male Branch Tee Fitting

- Instrument Union Cross Fitting

- Instrument Tube Cap Fitting

- Instrument Pipe Plug Fitting

- Instrument Male Connector Fitting

- Instrument Female Connector Fitting

- Instrument Female Adapter Fitting

- Instrument Male Adapter Fitting

- Instrument Bulkhead Union Fitting

- Instrument Equal Union Fitting

- Instrument Reducing Adapter Fitting

- Instrument Pipe Coupling Fitting

- Instrument Valve

- Cam & Groove Coupling

- Butt Weld Fitting

- Stainless Steel 90 Degree Butt Weld Elbow Fitting

- Stainless Steel 45 Degree Butt Weld Elbow Fitting

- Stainless Steel Equal Tee Butt Weld Fitting

- Stainless Steel Reducer Butt Weld Fitting

- Stainless Steel Cap Butt Weld Fitting

- Stainless Steel Stud End Butt Weld Fitting

- Carbon Steel 90 Degree Butt Weld Elbow Fitting

- Carbon Steel Equal Tee Butt Weld Fitting

- Carbon Steel Reducer Butt Weld Fitting

- Forged Steel Fitting

- Sanitary Valve

- Forged Flange

- Water Meter

- Brass Fitting

- Cast Steel Valve

- Forged Steel Valve

- Bellows Seal Globe Valve

- Float Steam Trap

- Butterfly Valve

- Service

- About

- Info

- Contact

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search